PHS Compliance

Qi’s established client phs compliance, part of phs group, approached us with a view to adapting and optimising some of our own previous specifications to install into their batch of new model Vauxhall Vivaro vehicles.

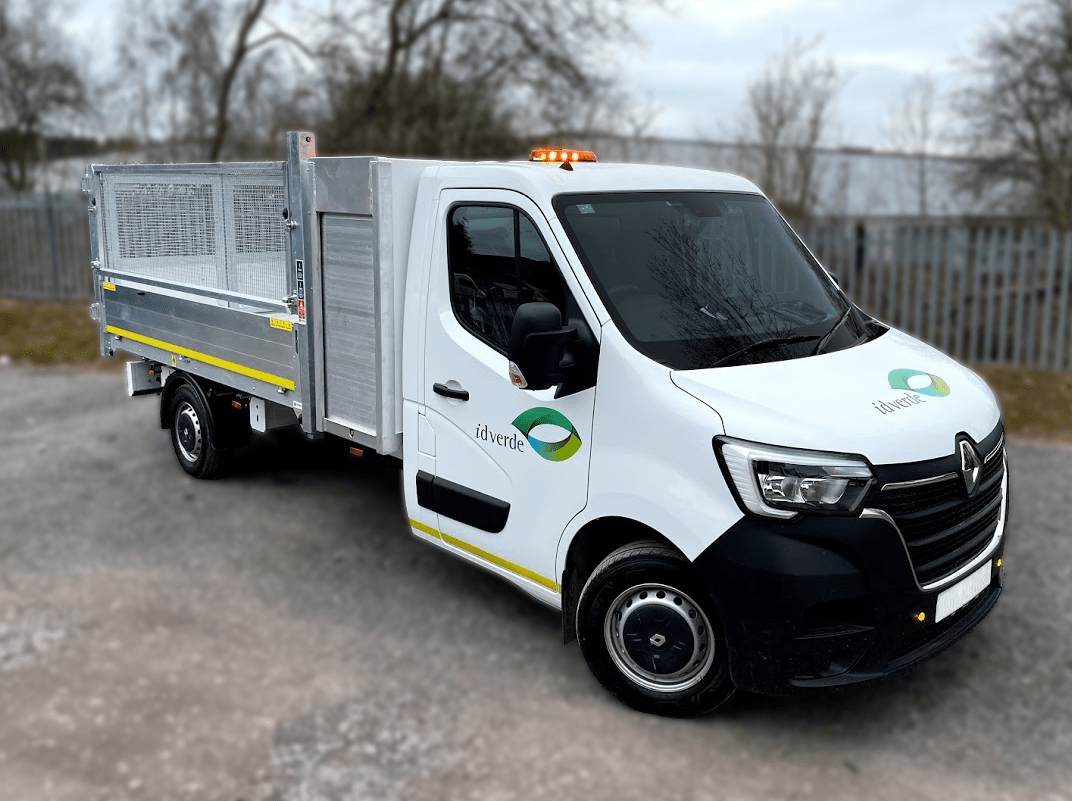

When idverde are awarded a contract, the Fleet Team work with our Key Account Managers to put together conversion specifications that are required to fulfil that specific contract. This has resulted in the current catalogue containing over 30 specifications, involving a range of vehicle variations from 3 different vehicle manufacturers.

As we design and manufacture bespoke racking on site in Telford, it gives idverde a level of flexibility with their specifications for each contract.

Alongside the information given to create the different specifications, the Fleet Team provide us with the volume of vehicles required, the dates of vehicle availability, and project timescale for delivery. idverde also set up vehicle Purchase Orders directly with Manufacturers, and provide ample time for the supply chain partnerships to deliver the completed working vehicle asset in a timely fashion. Each specification goes through a Prototype build at Qi, which ensures that build is fully documented and approved by idverde, ensuring consistency throughout the fleet.

The idverde Fleet Team are often engaging with operators and feeding information back to us during the prototyping process, enhancing the vehicle and tipper conversions, to ensure that health and safety practices are adhered to, with operator safety at the forefront of their minds.

We work closely together to monitor all fitments throughout the build process. Each vehicle may have a different livery requirement, so this information is passed through to us from the Fleet Team, where our in-house Graphics department produce and apply each Graphics pack to individual chassis’.

As well as looking after livery, we help to monitor any tracker requirements on site in Telford, whereby a third party is advised of vehicle arrivals and scheduled build weeks, to ensure that Trackers are fitted in-line with projected build completion dates. We also work with the relevant Manufacturers, to ensure that vehicles are either PDI’d on site in Telford, or with the chosen dealership, dependant on the end-destination of the vehicle (monitoring any unnecessary mileage and movements).

At completion, vehicles go through a meticulous QC Process to ensure that all fitments are completed to the level expected by all parties.

Alongside build in Telford, Qi also offers an After-sales services for idverde. Our After-sales team can attend site for Warranty Repairs or Retrofit projects, and can also supply parts to nominated garages. As mentioned above, our Graphics department are able to produce Livery Packs, which our After-sales team can supply to idverde directly if a vehicle has a requirement to change location or contract.

Working closely with idverde, we have been able to fine-tune our processes alongside the requirement of their Fleet Team, to ensure that all vehicles are completed in ample time to allow idverde to have a seamless vehicle introduction for their contracts.

Tippers & Dropsides

idverde

“Since we started using Qi Van Systems early in 2016 they have been nothing but professional in their approach taking time to get things right first time, even when things don’t go to plan and it does happen they come up with solutions based not just on what they think but more importantly, what our business needs.

Quality of workmanship has never been an issue as has their ability to listen to the customer and work through problems to achieve workable solutions, this has extended to new vehicle builds which are outside their normal area of expertise but on which they take time to make sure the finished product is fit for purpose.”

Angus Lindsay,

Group Head of Assets and Fleet

idverde

Get in touch so we can better understand you and your specific conversion requirements

Contact us